- Home

- Production and QA Equipment

We possess advanced manufacturing processes and equipment, including SMT, PTH/DIP soldering assembly systems, AOI (Automated Optical Inspection) machines, precision PCB cutting machines, and automated moisture-proof coating dispensers.

We are committed to capital investment to deliver greater production capacity and exceptional service.

DEK Screen Printer

Accuracy level down to +/- 0.025mm,

Cpk 1.33

Fast Speed Juki SMT System

Smallest chip size: 0201

BGA & QFP minimum pitch: 0.4mm

PCB size of 410mm X 360mm

Heller Lead-free Hot Air Reflow Oven

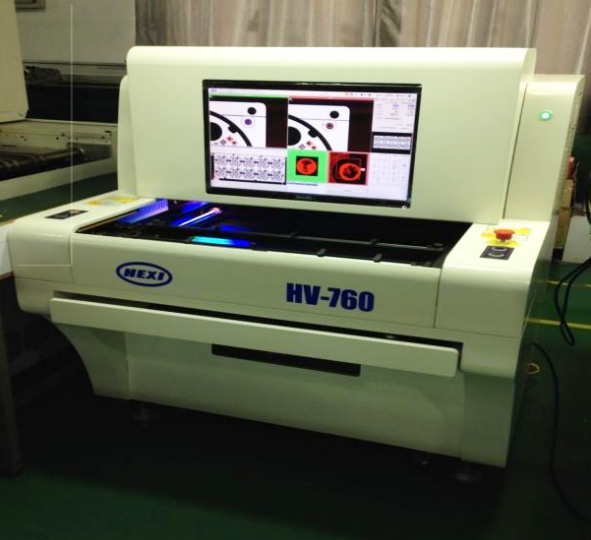

AOI & BGA Workstation

SMT Production Line

DEK Printer, Juki mounter and reflow oven linked as an automatic SMT line. ICT is normally done right after SMT.

RoHS Shop Floor

RoHS shop floor for RoHS-only products, anti-static floor, benches and other production equipments provide ESD protection to sensitive products.

Cell-Line Assembly

Suitable for high complexity, low volume products or NPI items.

Belt-Line Operation

Belt-line mode operation at wave soldering line with high efficiency.

Conformal Coating

Air-ventilated conformal coating facility. Silicone-based / Acrylic-based coating option available.

Two-component Potting

Ratio-variable potting to fit the requirement for various adhesives, Epoxy or silicone.

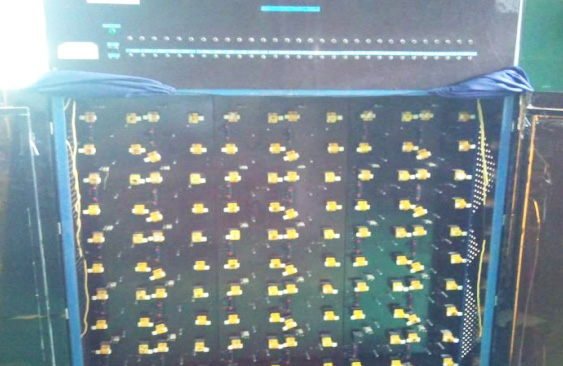

Burn-in Rack for LED Lamps

Suitable for high volume functional / reliability testing.

Computer-Controlled Ageing

Up to 300 +/- 5 deg. Celsius.